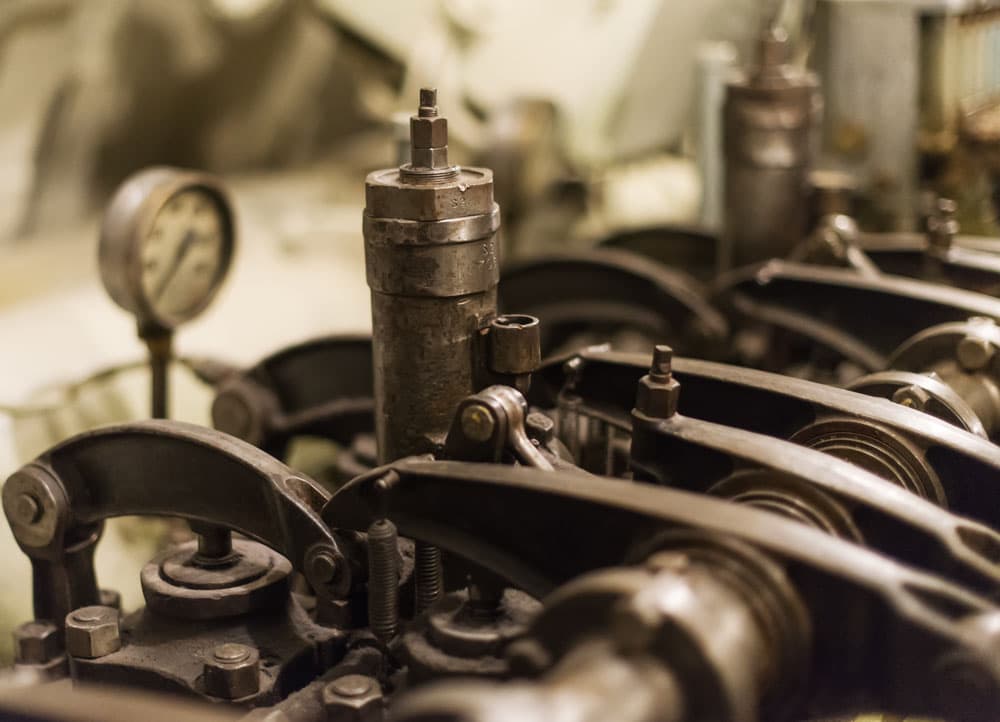

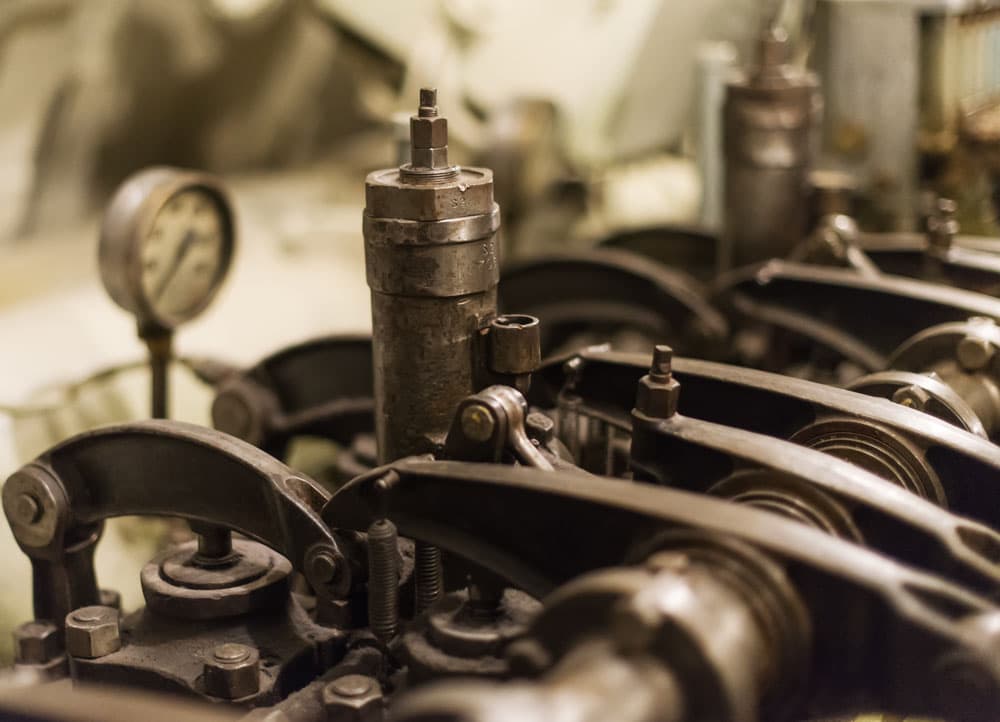

REPAIR AND MAINTENANCE

OF MARINE ENGINES

We work for you 365 days a year quickly, competently and on schedule. On the continents of Europe, Asia, Australia and America.

REPAIR AND MAINTENANCE

OF MARINE ENGINES

We work for you 365 days a year quickly, competently and on schedule. On the continents of Europe, Asia, Australia and America.

The Wehrenberg company is a Hamburg-based company based in Finkenwerder. In the field of repair, maintenance and repair of ship engines and stationary diesel engines. We carry out work and installations on cargo ships and salvage tugs under our own direction and responsibility. A qualified team of 6 specialists has been conscientiously carrying out all these tasks since 1970.

We have specialized in 4-stroke engines from 20Kw to 12.500Kw.

We work for you 365 days a year quickly, competently and on schedule. The locations are spread over the continents of Europe, Asia, Africa and America. In the 400 m² workshop hall, lathes and machine tools are available for machining cylinder heads, pistons and cylinder liners.

These include a portable honing machine for the MAN 32/40, 40/54, 48/60 and 58/64 engine types and other engine types, as well as modern Hunger valve seat milling machines and valve grinding machines.

Pistons are measured in the annular grooves and shoulder clearance and reworked if necessary.

We dismantle the cylinder heads in our assembly hall, measure all parts such as valve seats, valves, valve guides and rework them with Hunger equipment. In addition, the valves are glass bead blasted, tested and flat surfaces checked for cracks. We can also easily replace valve guides with our stand press. All overhauled heads are then tested at 10 bar water pressure.

Disassemble the connecting rods, clean them, tighten them according to the manufacturer's instructions and measure them for roundness. Piston pin bushes are pulled with a press according to the findings, new bushes are inserted with nitrogen.

Repair of MAN 40/54, 48/60 and Deutz 510, 645 exhaust valve housings.

Repair of cooling water and oil pumps of all manufacturers.

Repair of charge air coolers, cooling water pressure test according to manufacturer's specifications.